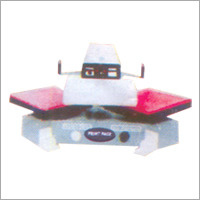

Automatic Heat Press machine

Product Details:

- Condition New

- Product Type Double Pad Fusing Machine

- Dimension (L*W*H) 1500 mm x 820 mm x 1150 mm

- Application Garment/Textile Industry

- Printing Method Thermal Fusing

- Head Size 400 mm x 150 mm

- Weight 180 kg

Automatic Heat Press machine Price And Quantity

- 1 Unit

- 50000 INR/Unit

Automatic Heat Press machine Product Specifications

- Double Pad Fusing Machine

- New

- 1500 mm x 820 mm x 1150 mm

- Garment/Textile Industry

- Thermal Fusing

- Blue and Grey

- 600 pieces/hour

- 180 kg

- 400 mm

- 400 mm x 150 mm

Automatic Heat Press machine Trade Information

- 100 Unit Per Month

- 20 Days

- Normal Packaging

- All India

Product Description

As one of Indias leading manufacturers and suppliers, we are offering a qualitative range of Double Pad Fusing Machine. Offered range is used for fusing in fabrics. The fusing machine provided by us boasts of a special design, which lets it to handle high work load with the same ease as in normal conditions. Entire range is manufactured by super grade raw materials that increase work efficiency of Double Pad Fusing Machine.

Features:

- User friendly design

- Low maintenance

- Long service life

Sizes Available:

6x 4, 6 x6, 16 x 20, 20 x 24, and 20 x 30

Specification

|

Brand |

KSC |

|

Usage/Application |

Garments |

|

Capacity |

150 Piece Per Hours |

|

Material |

Mild Steel |

|

Size |

20 x 24 inch |

|

Max Temperature |

250 degree celsius |

|

Voltage |

240 V |

|

Automation Grade |

Automatic |

|

Heating Time |

25 Sec |

|

Country of Origin |

Made in India |

|

Frequency |

50 Hz |

|

Phase |

Three Phase |

Efficient Thermal Fusing Technology

Harness the reliability and precision of our Automatic Heat Press Machine, which features an advanced thermal fusing method. This process ensures uniform heat distribution, resulting in crisp, long-lasting prints on garments and textiles. Ideal for rapid production environments, users benefit from the efficient operation and high throughput that meets demanding industry needs without compromising on quality.

Spacious and Durable Design

Designed with generous overall dimensions and a substantial head size, this machine accommodates a wide range of textile items. The printing width of 400 mm provides versatility for various garment sizes, while the machines solid construction at 180 kg guarantees stability during high-speed operation. The blue and grey finish adds a modern touch, making it an attractive addition to any production floor.

FAQs of Automatic Heat Press machine:

Q: How does the thermal fusing process work in this heat press machine?

A: The thermal fusing process in the Automatic Heat Press Machine uses controlled heat and pressure to bond designs onto garments and textiles. This ensures even, durable prints that can withstand frequent washing and wear.Q: What types of garments or textiles can be processed with this machine?

A: This machine is well-suited for a wide variety of garments and textile materials commonly used in the apparel industry, including t-shirts, uniforms, and other fabric items that require high-quality prints.Q: When is this automatic heat press most beneficial for production?

A: The machine is particularly advantageous during large-scale production runs where speed and consistency are crucial. With its capacity to process up to 600 pieces per hour, it excels in high-demand situations.Q: Where can this machine be supplied or exported from?

A: As an exporter, manufacturer, supplier, and trader based in India, we provide this machine to clients both domestically and internationally, supporting global textile and garment production needs.Q: What is the recommended usage process for optimal print quality?

A: For best results, ensure garments are properly aligned on the 400 mm x 150 mm head, set the appropriate temperature and pressure based on material type, and allow the full cycle time for each print. Routine maintenance also preserves performance.Q: What are the main benefits of using this automatic heat press machine?

A: The key benefits include efficient mass production, consistent and high-quality prints, ease of use, and durable machine construction. These advantages contribute to increased productivity and lower operational costs for textile businesses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+