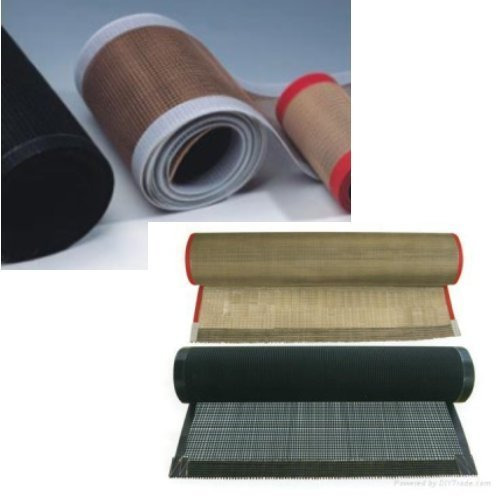

PTFE Coated Belt

Product Details:

- Type Coated Belt

- Material PTFE (Polytetrafluoroethylene) Coated Fiberglass

- Density 2.3 Gram per cubic centimeter(g/cm3)

- Corrosion Protection Excellent

- Tensile Strength High

- Thickness 0.13 mm to 1 mm

- Melting Point 327C

50000 INR/Unit

X

PTFE Coated Belt Price And Quantity

- 50000 INR/Unit

- 1 Unit

PTFE Coated Belt Product Specifications

- PTFE (Polytetrafluoroethylene) Coated Fiberglass

- High

- 2.3 Gram per cubic centimeter(g/cm3)

- As per requirement (commonly up to 100 m)

- 0.13 mm to 1 mm

- 327C

- 10 mm to 4000 mm (customizable)

- Excellent

- Custom sizes available

- Coated Belt

PTFE Coated Belt Trade Information

- 100 Unit Per Month

- 20 Days

- Normal Packaging

- All India

Product Description

We are a veteran as well as profound manufacturer and supplier of PTFE Coated Belt. Our belts are manufactured with premium quality of raw materials procured from trusted vendors of market. These belts are known for their long service time and reliable quality. Our entire stock is available in wide range of sizes and lengths to cater the demand of market. We offer PTFE Coated Belt to our clients at best of the market prices.

Features:

- Light weight

- Low maintenance

- Long life

Versatile Customization to Match Industrial Demands

Our PTFE Coated Belts offer unmatched flexibility in size, color, and edge reinforcement, making them suitable for a wide range of industries. You can choose from several joint types, including Alligator, Overlap, or customized solutions, ensuring the right fit for your specific machinery or process needs.

Exceptional Resistance for Harsh Environments

These belts deliver superior performance under extreme temperatures, corrosive settings, and exposure to flames or UV, thanks to PTFEs inherent properties. This makes them ideal for continuous industrial processing in challenging environments, enhancing equipment safety and belt longevity.

Applications Across Multiple Sectors

Whether in packaging, textile, food processing, heat sealing, or screen printing, our PTFE Coated Belts offer seamless, reliable conveyance, ensuring smooth operation and product integrity. Their high tensile strength and electrical insulation make them especially valuable in automated production lines.

FAQs of PTFE Coated Belt:

Q: How are PTFE Coated Belts installed and maintained for different applications?

A: PTFE Coated Belts can be installed using a range of joint types including Alligator, Overlap, Finger, or custom-designed joints to match application requirements. Maintenance involves routine inspection for wear, and cleaning with non-abrasive agents, as the PTFE surface resists most contaminants.Q: What advantages does the PTFE coating provide in industrial settings?

A: The PTFE coating imparts excellent non-stick properties, superior electrical insulation, resistance to high temperatures (up to 327C), flame resistance, and chemical and UV stability. This makes the belt reliable in demanding industrial processes, reducing downtime and extending the life of equipment.Q: When should one choose reinforced edges or Kevlar stitching for a PTFE Coated Belt?

A: Reinforced edges or Kevlar stitched belts are recommended when high tensile strength, precise tracking, or added durability are essentialsuch as in high-speed conveyors or heavy-duty processes. Choosing the right reinforcement depends on the specific mechanical stress of your application.Q: Where can PTFE Coated Belts be used most effectively?

A: These belts are utilized across a wide array of industries like packaging, food processing, heat sealing, shrink tunnels, textiles, and screen printing. Their unique features, such as high heat resistance and non-stick surfaces, make them especially useful in processes where cleanliness and temperature control are crucial.Q: What is the process for selecting the right PTFE Coated Belt size and configuration?

A: To select an appropriate belt, determine the required width, thickness (0.13 mm to 1 mm), length (up to 100 m or custom), joint type, and edge reinforcement based on your machine specifications and processing needs. Consultation with a manufacturer or supplier will help tailor the product to your exact operational requirements.Q: How does the PTFE Coated Belt contribute to safety and efficiency?

A: The belts flame resistance, electrical insulation, and non-stick PTFE surface reduce the risks of fire, short circuits, and product contamination, while improving material flow and process efficiency. These safety features are particularly valuable in food, packaging, and textile production environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email