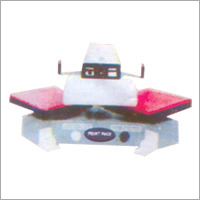

Automatic Double Pad Fusing Machine

Product Details:

- Weight 180 kg

- Printing Width 500 mm

- Printing Speed 600 pieces/hour

- Condition New

- Product Type Automatic Double Pad Fusing Machine

- Application Textile Garment Fusing

- Automatic Grade Automatic

Automatic Double Pad Fusing Machine Price And Quantity

- 1 Unit

- 50000 INR/Unit

Automatic Double Pad Fusing Machine Product Specifications

- Automatic

- Double Pad

- New

- 1200 mm x 800 mm x 1400 mm

- Pad Fusing

- Grey / Blue

- 180 kg

- 500 mm

- 600 pieces/hour

- Automatic Double Pad Fusing Machine

- Textile Garment Fusing

Automatic Double Pad Fusing Machine Trade Information

- 100 Unit Per Month

- 20 Days

- Normal Packaging

- All India

Product Description

In our extensive gamut of products, we bring forth for our clients Automatic Double Pad Fusing Machine. It is used for is used for shirts collar and cuffs with loading and unloading of pieces on the same side. We are blessed by experienced professionals who have in-depth experience in their concerned domain. The machine provided by us is manufactured under the stern guidance of our dexterous professionals using optimum quality materials. Moreover, our valuable clients can avail this Automatic Double Pad Fusing Machine from us at reasonable prices.

Features:

- Easy to operate

- Rugged design

- Hassle free functionality

Specification

|

Brand |

KSC |

|

Usage/Application |

Garments |

|

Capacity |

150 Piece Per Hours |

|

Material |

Mild Steel |

|

Size |

20 x 24 inch |

|

Max Temperature |

250 degree celsius |

|

Voltage |

240 V |

|

Automation Grade |

Automatic |

|

Heating Time |

25 Sec |

|

Country of Origin |

Made in India |

|

Frequency |

50 Hz |

|

Phase |

Three Phase |

Efficient Double Pad Fusing Technology

This machine utilizes an innovative double pad system, offering consistent fusing across a 500 mm width. The dual pads enable simultaneous processing, maximizing throughput and ensuring even adhesion on garments for superior results in textile production.

Optimized for High Production Demand

Designed to handle 600 pieces per hour, the Automatic Double Pad Fusing Machine is perfect for high-volume operations. Its automatic grade reduces manual intervention, streamlining the workflow for manufacturers, exporters, and textile suppliers seeking productivity gains.

User-Friendly Operation and Versatile Use

With a straightforward interface and durable construction, users find the machine easy to operate and maintain. Suitable for a variety of textile materials and garment sizes, it supports production flexibility without compromising on output quality.

FAQs of Automatic Double Pad Fusing Machine:

Q: How does the Automatic Double Pad Fusing Machine improve textile garment fusing processes?

A: The machine automates the pad fusing process, using a double pad head to fuse garments uniformly. This results in consistent quality and faster production, with a capacity of up to 600 pieces per hour.Q: What applications is this fusing machine suitable for?

A: It is specifically engineered for textile garment fusing in manufacturing settings, making it ideal for garment exporters, manufacturers, suppliers, and traders who require efficient, high-volume operations.Q: When should I consider using an automatic double pad fusing machine?

A: Consider using this machine when your production requires consistent, high-speed fusing of fabricsespecially in bulk garment manufacturing or export operationswhere manual processes are time-consuming and less reliable.Q: Where can this machine be effectively installed and used?

A: The fusing machine can be installed in textile manufacturing units, garment factories, export houses, and supplier warehouses throughout India, or wherever large-scale garment fusing is required.Q: What is the process followed by this automatic fusing machine?

A: Garments are placed on the machines double pads, which then apply controlled heat and pressure using the pad fusing method. Automatic operation ensures uniform adhesion across all processed materials.Q: How do I benefit from using this machine in my production line?

A: The main benefits include increased production speed, improved fusing consistency, reduced labor costs, and greater reliabilityideal for businesses focused on large quantities and tight deadlines.Q: What maintenance is required to keep the machine in optimal condition?

A: Routine cleaning of the pads and checking for any mechanical wear is recommended. Follow the manufacturers guidelines for scheduled maintenance to ensure longevity and consistent performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+